-

Мобильная дробилка

- запчасти для лабораторных дробилок

- Ледяная дробилка в Дубае

- дробилки для шлака цена

- операция шаровой мельницы и техническое обслуживание PDF

- изображения камнедробилки

- мельница шаровая outotec 6 7 * 11 3

- мокрый шлифовщик 1 литра

- кокосовое дробилка

- используется дробилка станции для продажи в России

- камнерезный станок wga

- носорог каменные дробилки камень для продажи jhb

- переменная мельница ролик в цементной модели 3700

- cara menanam 250 400 бутлуур

- валковая дробилка б у украина

- как кальцит используется в фотографии

- производитель дробилка для дробилки

- горнодобывающая промышленность золотой железа и фосфатов

- преимущества стержневой мельницы

- требования к техническому обслуживанию и затраты на целетон

- линия для производства щебня и песка

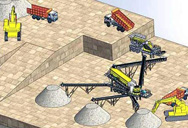

<процесс дробильной установки для

Линия по производству песка и щебня ...

Комплексная линия по производству песка и щебня состоит из щековой дробилки, молотковой дробилки, конусной дробилки, ударной дробилки, виброгрохота,

Read More

Мини Линия По Производству Щебня ...

Мини-линия по производству щебня обычно состоит из нескольких ключевых компонентов, которые работают в тандеме для преобразования сырья в основные

Read More

Линия для производства щебня и песка ...

Оборудование для производства кубовидного щебня и песка Компания «Лимин» специализируется на разработке и выпуске различных дробилок для производства

Read More

Линия по производству щебня и песка ...

Существует 2 варианта конфигурации производственной линии по производству щебеночного песка производительностью 500 т / ч, которая является практичной и

Read More

Линия по производству щебня ...

Оборудование линии по производству щебня в основном состоит из вибропитателя, щековой дробилки, ударной дробилки, ударной дробилки,

Read More

Технологические линии добычи песка ...

Проектирование и разработка современных линий добычи инертных материалов, изготовление, поставка и запуск оборудования. Линии комплектуются элементами и ведущих европейских ...

Read More

линия для производство щебня ...

Kefid линия для производства щебня включает в себя вибрационный питатель, щековая дробилка, роторная дробилка, конусная дробилка, грохот, конвейеры,

Read More

Преимущества линии для производства ...

Каковы преимущества линии для производства щебня и песка компании ЗАО Лимин? 1. Изнашиваемые детали изготовлены из новых отечественных

Read More

Линия для производства песка

Искусственный песок на рынке. Постоянный рост интенсивности и скорости движения автомобильного транспорта требуют строительства новых дорог.

Read More

Линия дробильно сортировачная по ...

Линия для производства щебня ... щебня иЛиния дробильно сортировачная по производству щебня и песка Линия по производству песчаного песка в Пакистане 120 т / ч речной каменной песчаной ...

Read More

Сколько щебня в 1 м3 бетона (песка и ...

Марка бетона М100: расход щебня 6.1 и 4.1 песка; М150: 5 щебня и 3.2 песка; М200: 4.2 щебня и 2.5 песка; М250: 3.4 щебня и 1.9 песка; М300: 3.2 щебня и 1.7 песка; М400: 2.4 щебня и 1.1 песка; М450:

Read More

Оборудование для производства песка ...

Плавучий агрегат сортировки щебня и песка из пгс, АС-263 . Доставка из г. Нижний Новгород В наличии Новое. Компания производит и поставляет агрегат –узел сортировки для плавучей горно-обогатительной установки.

Read More

линия по производству шебень и песка ...

Contribute to wulijing2022/ru development by creating an account on GitHub.

Read More

сортировочная линия для щебня ...

ДСУ 30 – дробильно-сортировочная установка : Стройпроект. Среди стандартных наибольшую ...

Read More

Комплект сит КП-109/1 ГОСТ 8269.0-97 для песка ...

ГОСТ 8269.0-97 Щебень и гравий из плотных горных пород и отходов промышленного производства для строительных работ. Методы физико-механических испытаний (с Изменениями n 1, 2, с Поправками).

Read More

Линия для производства щебня и песка ...

Линия для производства щебня и ... Преимущества кубовидного щебня и песка для строительства и обслуживания дорог очевидны: повышение плотности укладки, ...

Read More

Галька, щебень и песок – применение в ...

2017.6.19 Используется для производства бетонных смесей, тротуарной плитки, шлакоблока и каменной ваты. На вопрос о весе и плотности щебня различных типов ответит следующая таблица:

Read More

вибропитатель для гравия

вибропитатель для дробления камня. Линии по Производству Камня 30-40 твч в Кении Дробильный Комплекс для гравия 400-450 т/ч в Гане каменные дробилки пригодны для дробления камня на маленькие фракции или на хорошие фракции.

Read More

Производства песка и щебня, купить в ...

Ранние здания, дороги и другие отрасли промышленности используют природный песок, с целью охраны окружающей среды, появляется искусственный песок, наряду с все более сложных объектов для производства щебня.

Read More

Линия для производства щебня и песка ...

Линия для производства щебня и ... Преимущества кубовидного щебня и песка для строительства и обслуживания дорог очевидны: повышение плотности укладки, ...

Read More

Линия для производства щебня и песка ...

Линия для производства щебня и ... Преимущества кубовидного щебня и песка для строительства и обслуживания дорог очевидны: повышение плотности укладки, ...

Read More

Линия для производства щебня и песка ...

Линия для производства щебня и ... Преимущества кубовидного щебня и песка для строительства и обслуживания дорог очевидны: повышение плотности укладки, ...

Read More

Дробильно-сортировочные комплексы для ...

Дробильно-сортировочные комплексы для производства щебня и песка Оборудование для производства щебня и гравия, Линия для производства песка и гравия (промывка и сортировка ПГС), Дозирующе-смесительное устройство ...

Read More

Фодамон – Дробильное оборудование ...

o компании. Наша основная продукция включает различные типы дробилок: щековые, роторные, конусные, в том числе мобильные; оборудование по промывке щебня и песка; шаровые мельницы и вращающиеся печи; вибрационные ...

Read More

линия дробления щебня прайс – машина ...

машина для производства и стирания песка ... линия дробления щебня прайс ... Технологическая линия для дробления известняковый щебень Запрос на прайс-лист Онлайн поддержка.

Read More

Линия для производства щебня и песка ...

Линия для производства щебня и ... Преимущества кубовидного щебня и песка для строительства и обслуживания дорог очевидны: повышение плотности укладки, ...

Read More

линия производства кубовидного щебня.md

Contribute to baacnzhuavrng/ru development by creating an account on GitHub.

Read More

Производства песка и щебня, купить в ...

Ранние здания, дороги и другие отрасли промышленности используют природный песок, с целью охраны окружающей среды, появляется искусственный песок, наряду с все более сложных объектов для производства щебня.

Read More

Линия по производству песка и щебня ...

Комплексная линия по производству песка и щебня состоит из щековой дробилки, молотковой дробилки, конусной дробилки, ударной дробилки, виброгрохота, водоотливного черпального колеса и ленточного конвейера.

Read More

линия для производства песка и щебня ...

Линия для производства песка и гравия В 2012 г была осуществлена поставка и пуск линии для ... Дробление песка Линия для щебня дробления и производства песка Оборудование для ...

Read More

линия для производства песка и щебня ...

Contribute to wulijing2022/ru development by creating an account on GitHub.

Read More

Дробильное линия для производства щебня

Дробильное линия для производства щебня в Ташкенте, цена 62600 от ИП ООО "BEST MACHINES" - купить оптом и в розницу во всех городах Узбекистана на Stroyka.uz

Read More

Линия для производства песка

Резюме:Оборудование и линия для производство песка Шибан занимает первое место в рынке Искусственный песок на рынке. Постоянный рост интенсивности и скорости движения автомобильного транспорта требуют ...

Read More

Производственная Линия для ...

Комплекс Для Производства Искусственного Песка. Зенит Комплекс по производству искусственного песка широко используется в строительной промышленности. Узнать Больше

Read More

производственная линия щебня – машина ...

Производственные линии дробильная машина для песка 10 окт 2014 . Архив рубрики ...

Read More

линия производства кубовидного щебня ...

Производство Кубовидного ЩебняПолучение Кубовидного Щебня. Центробежная ударная дробилка vsi5x для Производство кубовидного щебня.Дробильно-сортировочная линия с центробежной ударной дробилки vsi5x обеспечивают

Read More

линия для производства песка из щебня

Линия по производству щебня и песка_ План ...2020.11.11 Линия по производству щебня и песка представляет собой комбинацию множества оборудования, используемого для производства Read More

Линия по производству щебня и песка_ План ...2020.11.11 Линия по производству щебня и песка представляет собой комбинацию множества оборудования, используемого для производства Read More

линия производства песка и щебня в

Оборудование для производства песка, щебня ... 934 047 руб. Дробилка для производства искусственного песка и щебня, pe600*900, pe750*1060, pe900*1200, pe1000*1200.

Read More

линия по производству щебня и песка ...

Линия для производства щебня - ООО Хунцзи .... Линия » Линия для производства щебня. Линия для производства щебня. Потенциал : 50-800t/h. Материалы : гранит, базальта, банк гравий, бокситов.

Read More